NEXT 4.1

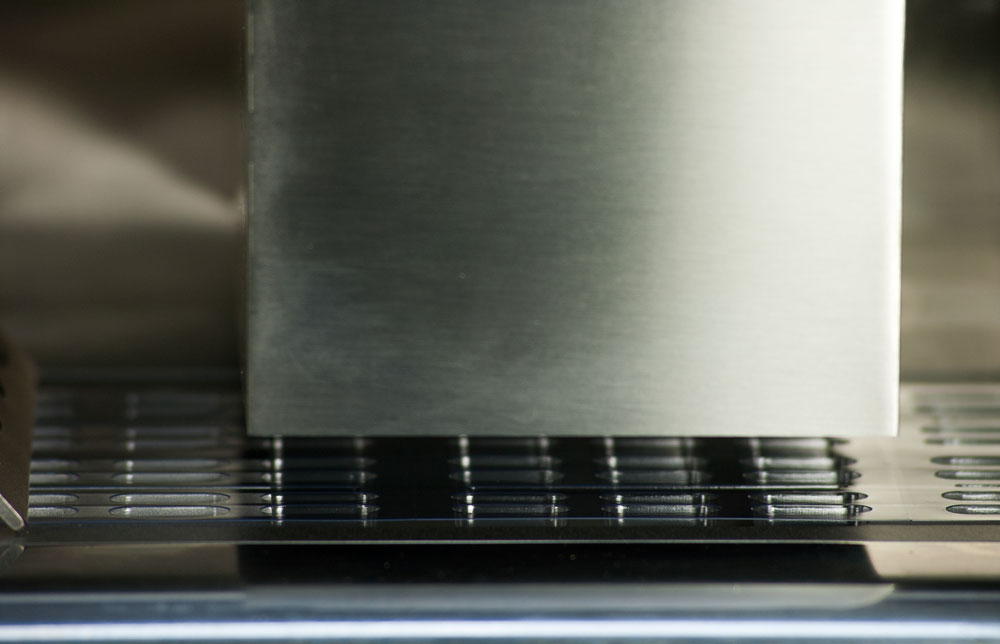

low/mid speed and affordable plate sealing thermoforming machine up to 60 trays per min

The manual loading machine perfection

Starting from our NEXT 4.0 we have add an extra 1000mm to reach a 1500mm manual loading space

If your production numbers are not big enought to start with an automatic loading the NEXT 4.1 is your perfect choice. Infact our NEXT 4.1 is conceived to pack big size solids or liquids, vials,carpoules, bottles, syringes, PFS, medical devices etc… with a multiple operators loading space

A constant control operated by advanced electronic devices working togheter with an algoritm on board helps us: maintain your machine permanently monitorized, predict the main machine’s fail, and guarantee, to the happy user of our NEXT 4.1 the maximum production rate.

Obviously when your needs will increase it will very easy, and quick, to add any automatic loading system

Flexible: From manual to robotized loading, the next 4.1 will follow your needs

Adaptabled: Huge loading area accessible from two sides to fit up to 4 operators

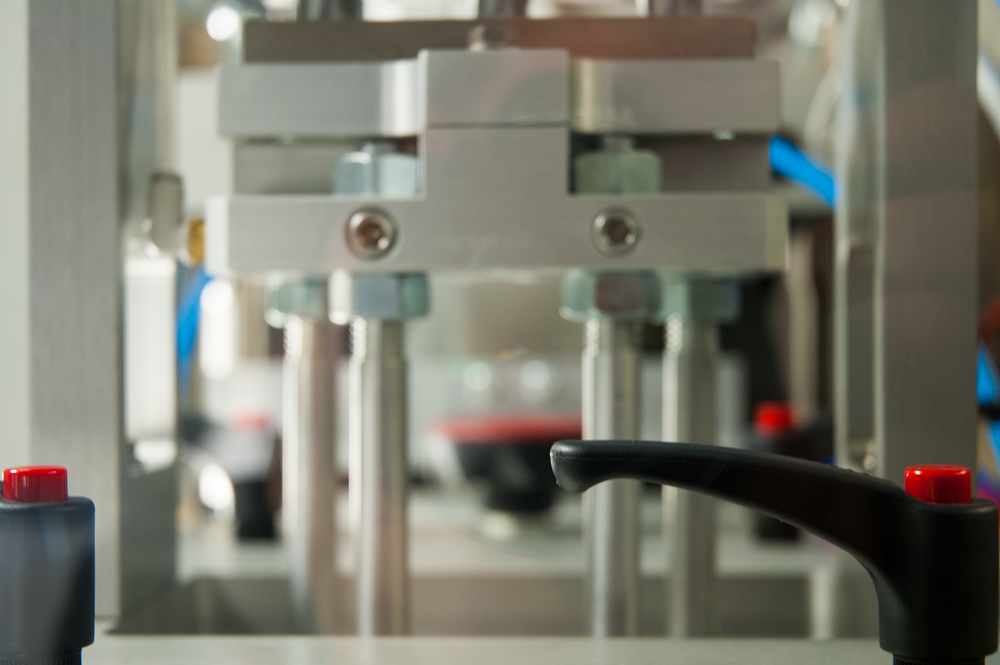

Top in quality: Equipped with Siemens PC, drives, and brushless motors.

Easy to use: Very easy HMI conceived starting from a mobile phone app.

Alpha gen. machine: Artificial Intelligence system on board to prevent fails and machine stops

Modular: You can decide how to compone your machine saving money and space

Worker friendly: Extremely accessible, to ensure easy cleaning and use .

Super fast format changing: Only 15’ for a total format change from syringes to vials/blisters/bottles

NEXT 4.1

Automatic thermoforming packaging machine

Technical specifications

| Maximum output per minute: | up to 60trays OR 80blister |

| Space required | Machine length: approximately 2600mm Machine hight: approximately 18654mm Machine width: approximately 1550mm |

| Machine net weight | approximately 1620Kg |

| Installed power | 7 Kw |

| Average power consumption | 2 Kw |

| Inlet air pressure | 6/8 bar |

| Average compressed air consumption | 150 N/L min (1bar) |

| Forming materials | PVC, PVC-PVDC, PVC-PE, PVDC, PVC-ACLAR, ACLAR, PP, PET, COC, TEKNIFLEX, AQUABA |

| Lidding materials | PAPER FOIL LAMINATE, PP, C R mat., ALU, TYVEK |

| Maximum width of forming film | 170 mm |

| Pitch | 100 mm |

| Maximum forming depth | 35 mm |

TECHNICAL SPECIFICATIONS

Max. output per min.

up to/fino 60trays or 80blisters

Space required:

Machine lenght: approx. 2600mm

Machine widht: approx. 1550mm

Machine hight: approx. 1854mm

Machine net weight

approximately 1620Kg

Installed power

7 Kw

Average electrical consumption

2Kw

Inlet air pressure

6-8 bar

Average compressed air consum.

150NL/min (1 bar)

Forming materials

PVC, PVC-PVDC, PVC-PE-PVDC,

PVC-ACLAR, ACLAR, PP, PET, COC

Lidding materials

ALU, PAPER FOIL LAMINATE, PP, C R mat.

Max. width of forming film

170mm

Pitch

100mm

Max. forming depth

35 mm

%

compactness

%

speed

%

ease to use

%

flexibility

THE ART OF THERMOFORMING MACHINES