BLIXT 2.5

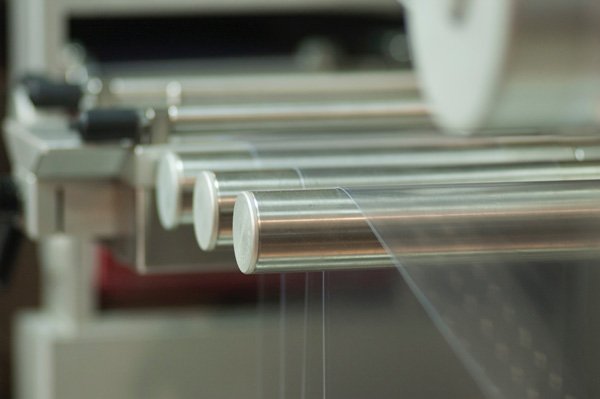

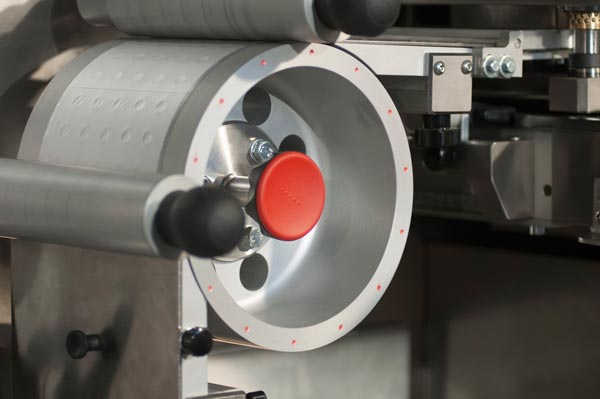

automatic blister packaging machine, roller sealing technology

Compactness, reliability and easly operated, all in one blister machine.

We believe that small packaging machines with high performance will become a must for the pharma, herbal and nutraceutical industry, because we all know how expensive the white room space has become.

We also believe that technology and beauty can be matched and, starting from this point, we have conceived the most compact, beautiful and efficient blister machine that money can buy.

In a balcony design with a length of only 2,98 mt we have used the most advanced technology in order to reach the remarkable speed of 250 blister/minute whit our automatic blister packaging machine BLIXT 2.5, without losing the most important characteristic of every machine: reliability, safety and easly operatable.

Compact Only 2,98 m in length to reduce the white room space and save money.

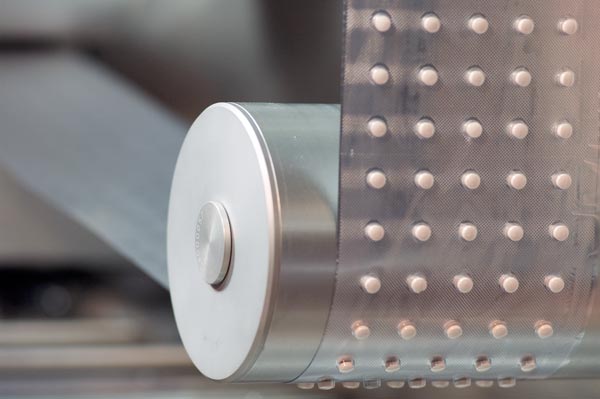

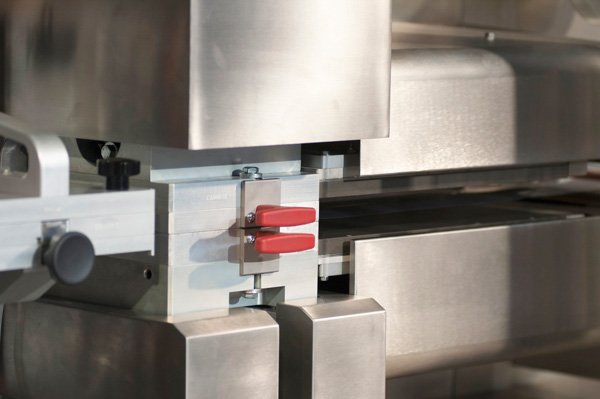

Efficient: Stable cutting system supported with new technology pre cutting drum.

Top in quality: Equipped with Siemens PC, drives, and brushless motors.

Ease of use: 15″ operator panel with an easy and intuitive human interface.

Worker friendly: Easy access to forming film reels, even with forklift.

Extremely fast format changing: Easy and very fast format changing.

Reliable: Controlled sealing roller station, for a perfect sealing.

Safety deposit: The blister’s deposit is from the cutting station on the exit belt.

BLIXT 2.5

Automatic blister packaging machine

Technical specifications

| Maximum output per minute: | up to 60 cycles and 250 blister |

| Space required | Machine length: approximately 2980 mm Machine hight: approximately 1890 mm Machine width: approximately 1325mm |

| Machine net weight | approximately 2210 Kg |

| Installed power | 16 Kw |

| Average power consumption | 3.5Kw |

| Inlet air pressure | 6/8 bar |

| Average compressed air consumption | 200 N/L min (1bar) |

| Forming materials | PVC, PVC-PVDC, PVC-PE, PVDC, PVC-ACLAR, ACLAR, PP, PET, COC, ALU, SBC TEKNIFLEX, AQUABA |

| Lidding materials | PAPER FOIL LAMINATE, PP, C R mat., ALU, TYVEK |

| Maximum width of forming film | 160 mm |

| Pitch | 180 mm |

| Maximum forming depth | 12 mm |

9TECHNICAL SPECIFICATIONS

Max. output per min.

up to/fino 250 blister

Forming cycles per min.

up to/fino a 60 cycles/cicli

Space required:

Machine length: approx. 2980 mm

Machine width: approx. 1325 mm

Machine hight: approx. 1890 mm

Machine net weight

approximately: 2210Kg

Installed power

16 Kw

Inlet air pressure

6-8 bar

Average compressed air consum.

200 NL/min (1 bar)

Forming materials

PVC, PVC-PVDC, PVC-PE-PVDC,

PVC-ACLAR, ACLAR, PP, PET, COC, ALU, SBC TEKNIFLEX, AQUABA

Lidding materials

ALU, PAPER FOIL LAMINATE, PP, C R mat., TYVEK

Max. width of forming film

160mm

Pitch

180mm

Max. forming depth

12mm

%

compactness

%

speed

%

ease to use

%

reliability

THE ART OF BLISTER MACHINES