FLEXT TF

mid/high speed and affordable plate sealing thermoformingr machine up to 200 trays per min

The thermoforming machine revolution

We have used the most advanced technology, our experience and our crazyness in order to reach our goal; design a thermoforming very easy to handle (electronic motorized stations), affordable, modular smart and… such a beauty!

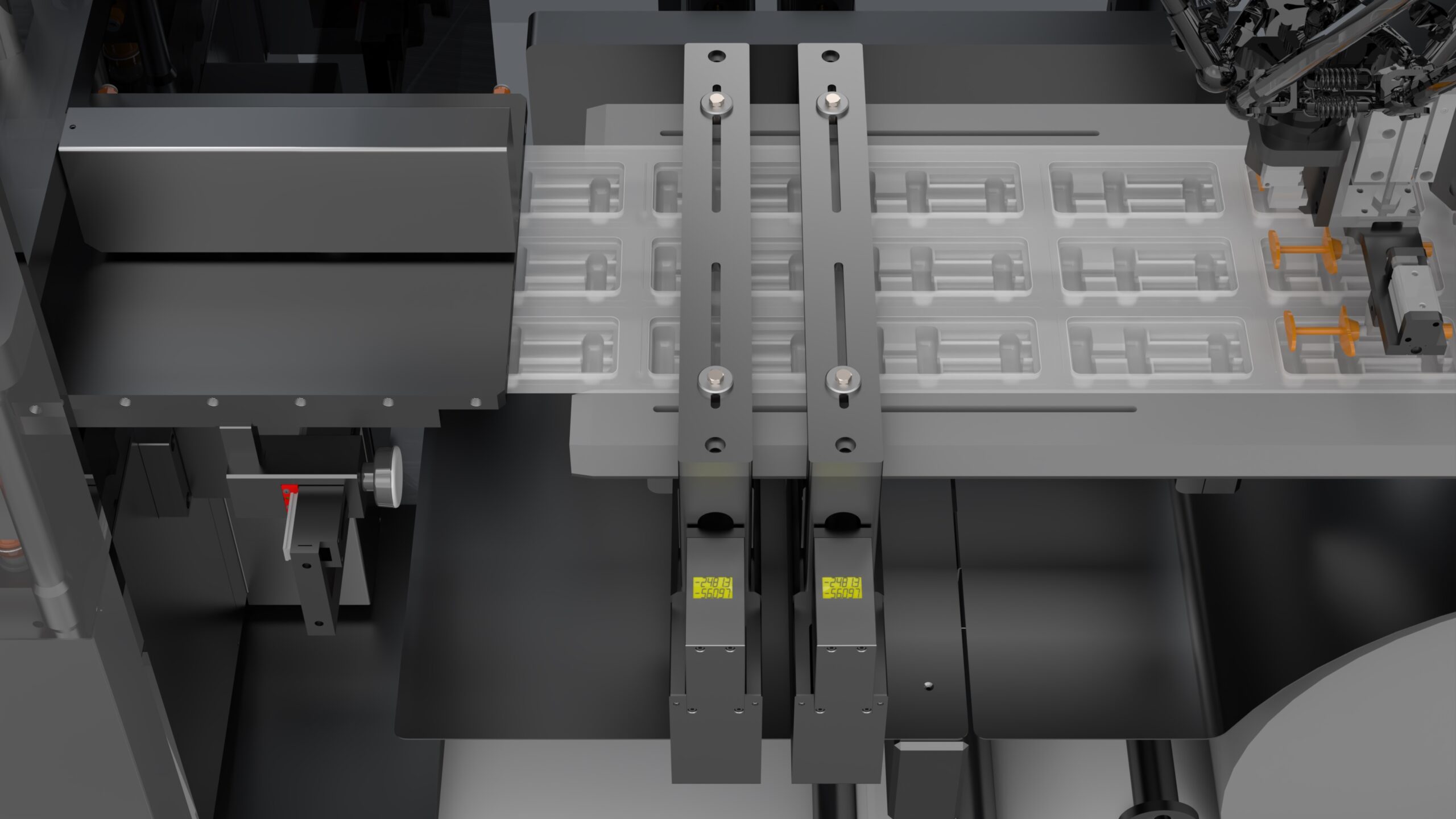

A completely new way of structuring the trays production. Our FLEXT TF is conceived to widen the range of products to be packed, infact the plate sealing technology permits you to pack big size solids or liquids, vials,carpoules, bottles, syringes, PFS, medical devices etc…

A constant control operated by advanced electronic devices working together with an algoritm on board to help us maintain your machine permanently monitorized, to predict the main machine’s fail, and helps guarantee, the happy user of our FLEXT TF the maximum production rate.

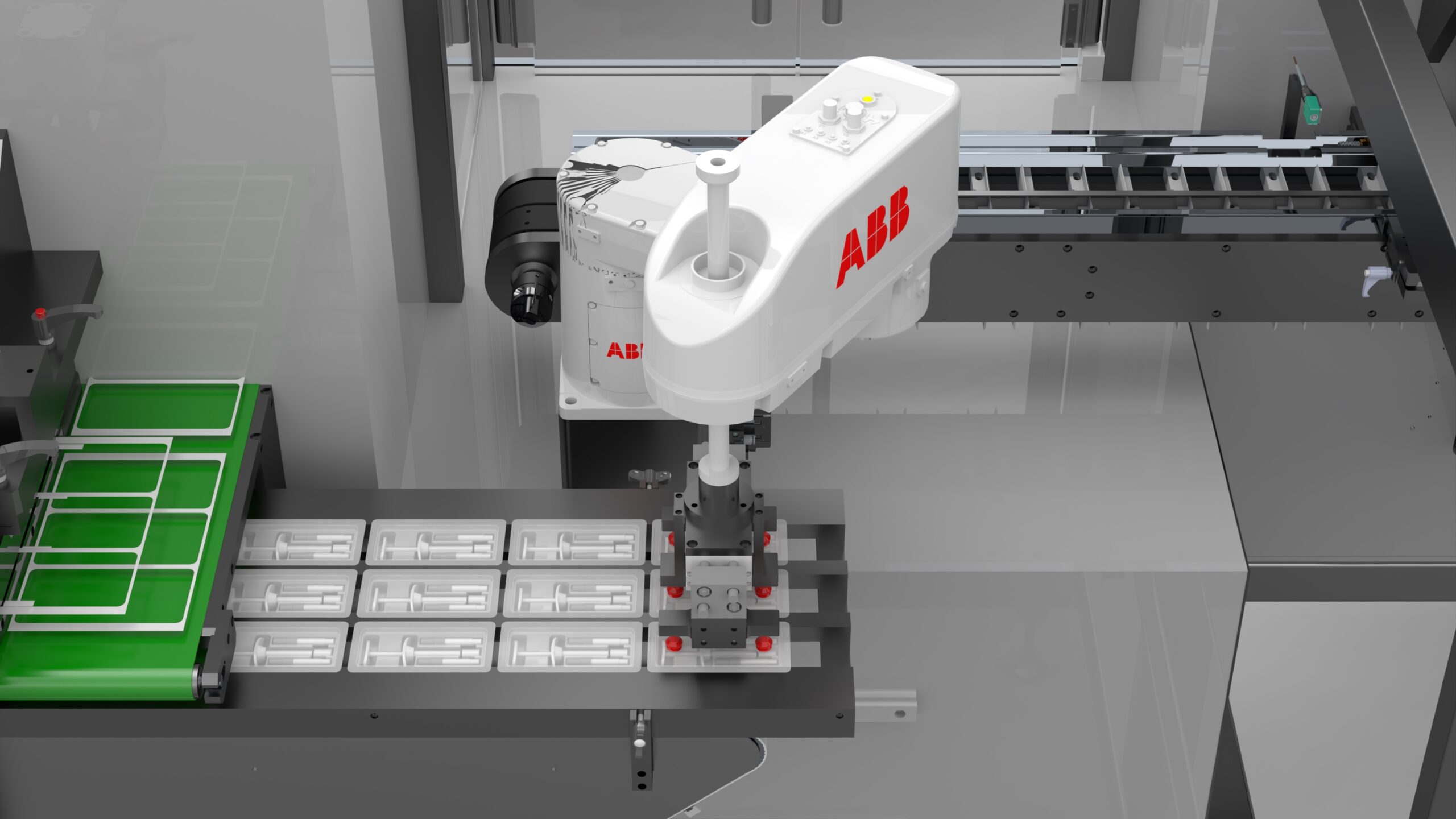

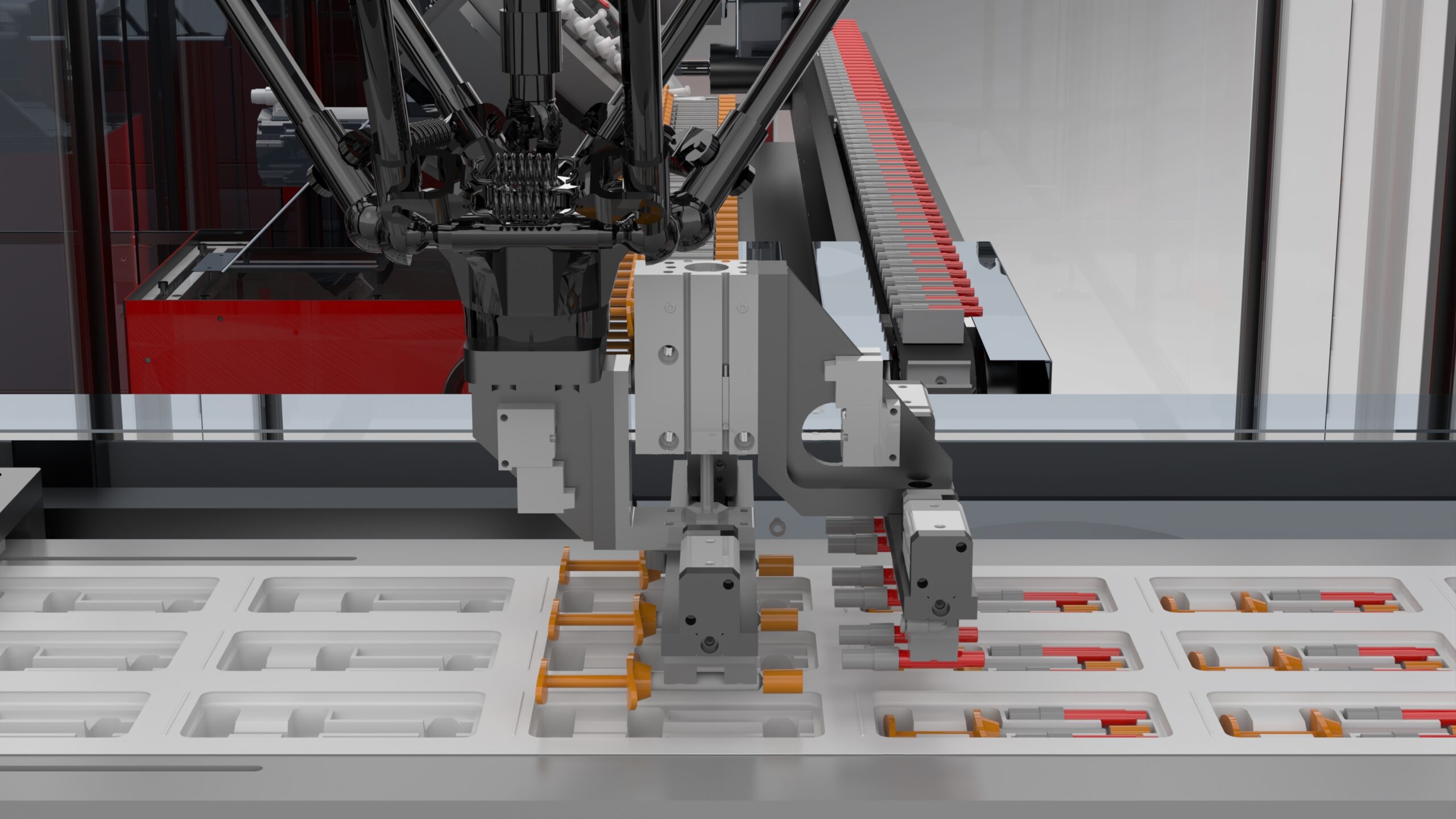

Flexible: Feeding, transfer and deposit means by ABB robot

Adapted: Revolutionary picker head to feed different products and handle syringes, vials, carpules, medical devices, food, coffe, candys.

Top in quality: Equipped with Siemens PC, drives, and brushless motors.

Easy to use: Electronic movement of the working stations that promptly reach and hold the pitch

Alpha gen. machine: Artificial Intelligence system on board to prevent fails and machine stops

Modular: You can decide how to compose your machine saving money and space

Worker friendly: Extremely accessible to ensure easy cleaning and use

Super fast format changing: Only 40’ for a total format change from syringes to vials/blisters/bottles

FLEXT TF

Automatic thermoforming packaging machine

Technical specifications

| Maximum output per minute: | up to 200 trays OR 45O blister |

| Space required | Machine length: approximately 6750mm Machine height: approximately 1860mm Machine width: approximately 1850mm |

| Machine’s net weight | approximately 4900Kg |

| Installed power | 7 Kw |

| Average power consumption | 3,5 Kw |

| Inlet air pressure | 6/8 bar |

| Average compressed air consumption | 150 N/L min (1bar) |

| Forming materials | PVC, PVC-PVDC, PVC-PE, PVDC, PVC-ACLAR, ACLAR, PP, PET, COC, TEKNIFLEX, AQUABA |

| Lidding materials | PAPER FOIL LAMINATE, PP, C R mat., ALU, TYVEK |

| Maximum width of forming film | 270 mm |

| Pitch | 170 mm |

| Maximum forming depth | 35 mm |

TECHNICAL SPECIFICATIONS

Max. output per min.

up to/fino 200 trays or 450 blisters

Space required:

Machine lenght: approx. 3800 mm

Machine widht: approx. 880 mm

Machine hight: approx. 1850 mm

Machine net weight

approximately 2300 Kg

Installed power

7 Kw

Average electrical consumption

3,5 Kw

Inlet air pressure

6-8 bar

Average compressed air consum.

200 NL/min (1 bar)

Forming materials

PVC, PVC-PVDC, PVC-PE-PVDC,

PVC-ACLAR, ACLAR, PP, PET, COC

Lidding materials

ALU, PAPER FOIL LAMINATE, PP, C R mat.

Max. width of forming film

270 mm

Pitch

170 mm

Max. forming depth

35 mm

%

compactness

%

speed

%

easy to use

%

flexibility

THE ART OF THERMOFORMING MACHINES