NEXT 4.0

the smallest and most convenient thermoforming machine on the market

3 X 1 + 4.0 X P = NEXT 4.0

Can a mathematical formula describe a packaging machine?

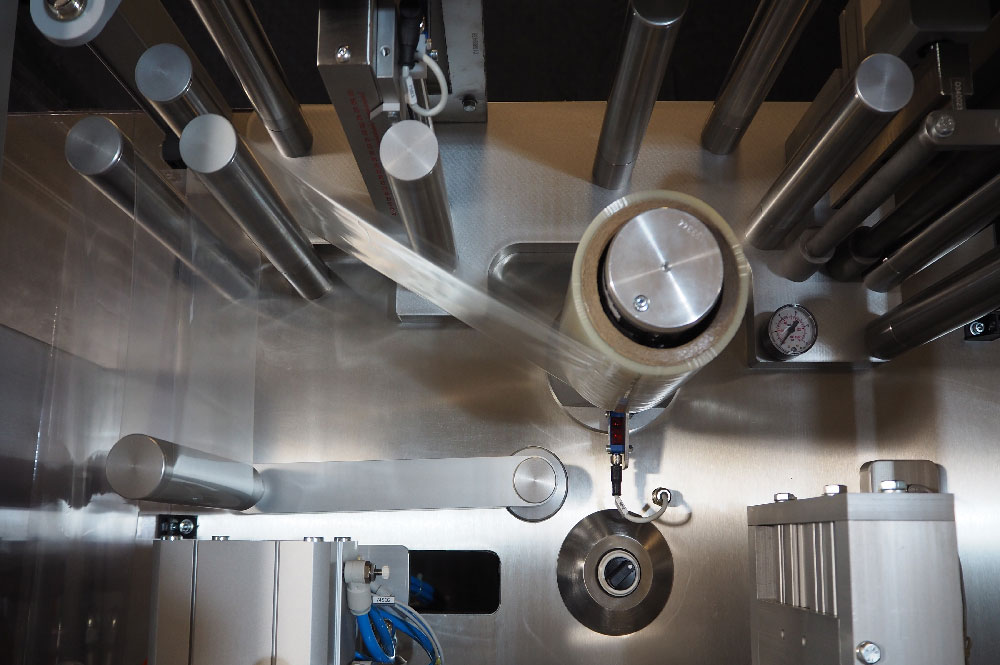

3X1: in less than 2m in length (pick and place excluded) we have created a 3 in1 machine: Blister, Thermoforming and a Test machine

4.0: the most advanced 4.0 electronic technology has been used to manufacture this machine

P: we have used the best ideas from the past and developed with the future. The main movements are mechanical and pneumatic, all the control systems are the best in the electronic market

Completely modular

Adding the pick and place module (1100mm)…

the NEXT 4.0 will turn itself in a completely automated thermoforming machine.

You can add the Pick & place module even after the machine’s set up, because of the presence in the NEXT 4.0 of electrical and mechanical connection

Hyper Compact Only 1900mm in length (pick and place excluded) to reduce the white room space and save money.

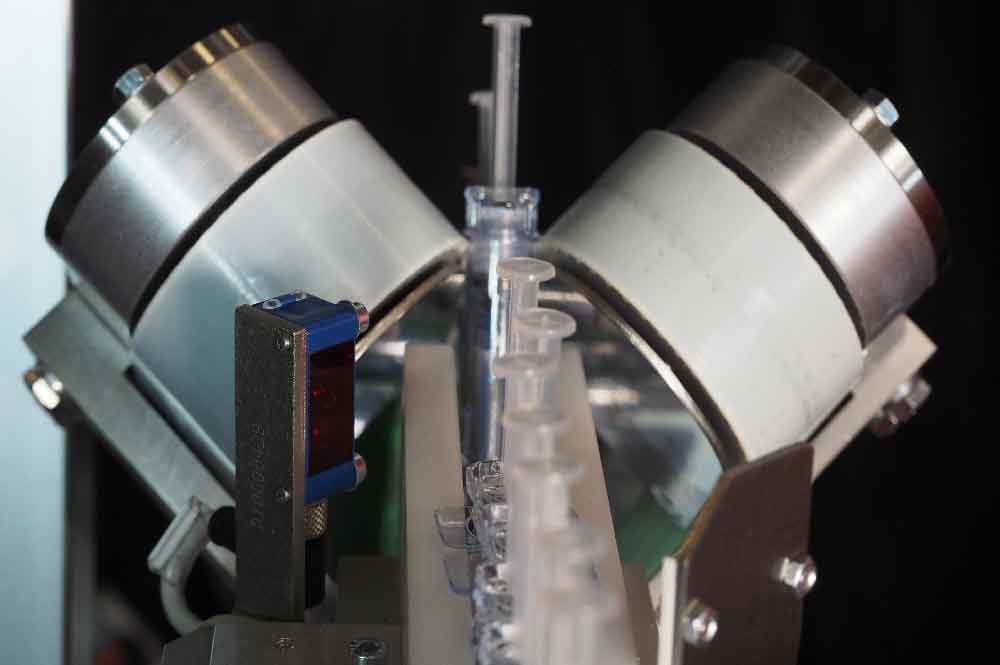

Adaptable: Blister, thermoforming and test machine in only one machine.

Top in quality: Equipped with Siemens PC, drives, and brushless motors.

Quick, easy and economically friendly format change: The fastest format changing available in less than 15 mins.

A huge range of feeding systems: The next 4.o easily allows feeding of solid, liquids and medical devices

Reliable: The main movements are mechanical or pneumatic, all the control systems are the best in the electronic market.

Lowest consumption ever: The average consumption during working cycle is only 2 KW/h

NEXT 4.0

Automatic blister, thermoforming and test packaging machine

Technical specifications

| Maximum output per minute | up to 40 cycles and 80 blister or 30 trays per minute |

| Space required |

Machine length: approx. 1900 mm Machine hight: approx. 1854 mm |

| Machine net weight | approximately 1620 Kg |

| Installed power | 7 Kw |

| Average power consumption | 2 Kw |

| Inlet air pressure | 6/8 bar |

| Average compressed air consumption | 150 N/L min (1bar) |

| Forming materials |

PVC, PVC-PVDC, PVC-PE, PVDC, PVC-ACLAR, ACLAR, PP, PET, COC, TEKNIFLEX, AQUABA |

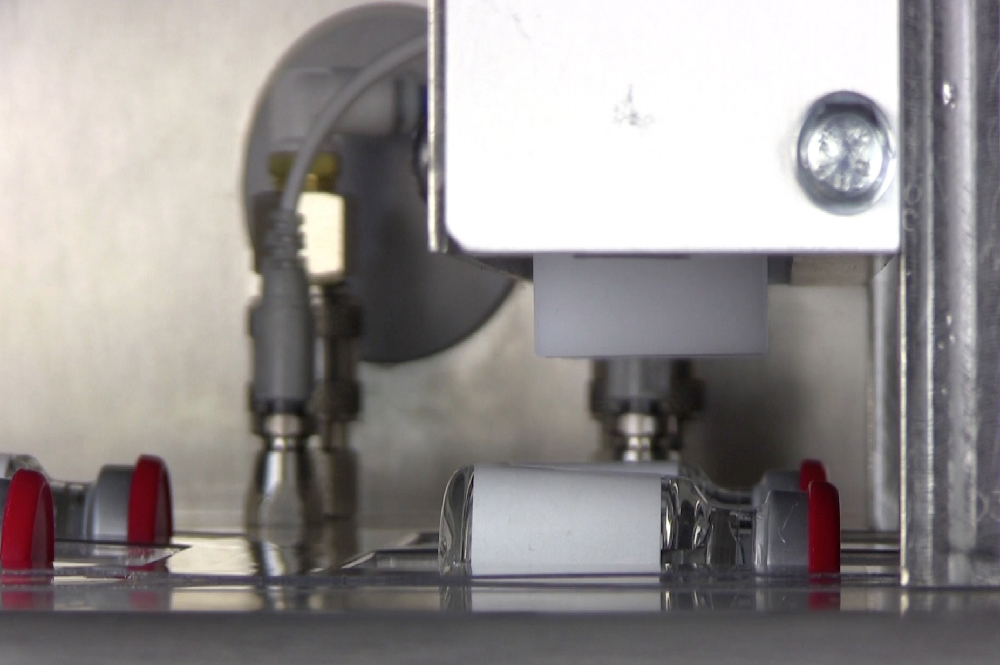

| Lidding materials | PAPER FOIL LAMINATE, PP, C R mat., ALU, TYVEK |

| Maximum width of forming film | 170 mm |

| Pitch | 100 mm |

| Maximum forming depth | 35 mm |

TECHNICAL SPECIFICATIONS

Max. output per min.

up to/fino 80 blisters or 30 trays

Forming cycles per min.

up to/fino a 40 cycles/cicli

Space required:

Machine length: approx. 1900 mm

Machine width: approx. 1550 mm

Machine hight: approx. 1854 mm

Machine net weight

approximately 1620 Kg

Installed power

7 Kw

Average electrical consumption

2 Kw

Inlet air pressure

6-8 bar

Average compressed air consum.

200 NL/min (1 bar)

Forming materials

PVC, PVC-PVDC, PVC-PE, PVDC, PVC-ACLAR, ACLAR, PP, PET, COC, TEKNIFLEX, AQUABA

Lidding materials

PAPER FOIL LAMINATE, PP, C R mat., ALU, TYVEK

Max. width of forming film

170mm

Pitch

100 mm

Max. forming depth

35 mm

%

compactness

%

speed

%

ease to use

%

flexibility

THE ART OF THERMOFORMING MACHINES